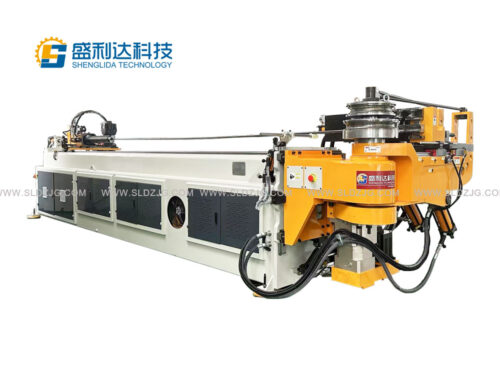

DW38CNC-3A-2S pipe bending machine is servo and hydraulic driven. The electrical appliances centrally control the bending angle, feeding accuracy, and pipe rotation accuracy. The bending machine head changes molds left and right. The hydraulic control clamping, guiding, and machine head upper and lower mold changes, mandrels, and mechanisms have their own independent cylinders. When the bending arm bends the pipe, under the control of the hydraulic system, the clamping, guiding, mandrel, and bending parts coordinate and cooperate to complete high-quality bending. It is an economical and practical general equipment.

The equipment can bend metal pipes with or without cores. The machine has actuation and single-action functions, which is easy to use and maintain. It is widely used in shipbuilding, boilers, chemicals, automobile manufacturing and other industries.

38CNC-3A-2S

Precise control through 3-13 axis servo motors;

Can realize left and right bending functions of 1-4 layer molds;

Can realize large radius or spiral product bending, with push bending function;

Industrial computer system has 3D interference inspection function;

Can connect robots and 3D measuring instruments, etc.

DW38CNC-3A-2S pipe bending machine is servo and hydraulic driven. The electrical appliances centrally control the bending angle, feeding accuracy, and pipe rotation accuracy. The bending machine head changes molds left and right. The hydraulic control clamping, guiding, and machine head upper and lower mold changes, mandrels, and mechanisms have their own independent cylinders. When the bending arm bends the pipe, under the control of the hydraulic system, the clamping, guiding, mandrel, and bending parts coordinate and cooperate to complete high-quality bending. It is an economical and practical general equipment.

The equipment can bend metal pipes with or without cores. The machine has actuation and single-action functions, which is easy to use and maintain. It is widely used in shipbuilding, boilers, chemicals, automobile manufacturing and other industries.

| Maximum bending diameter | Φ38*1.8 mm |

| Maximum curvature | 190° |

| Maximum feeding length | 2200mm(custom made) |

| Bending speed | 40 – 100°/ s |

| Feeding speed | 800mm/s |

| Corner speed | 160°/ s |

| Bending accuracy | ± 0.1° |

| Feeding accuracy | ± 0.1mm |

| Corner accuracy | ± 0.1° |

| Data input method | X Y Z OR Y B C |

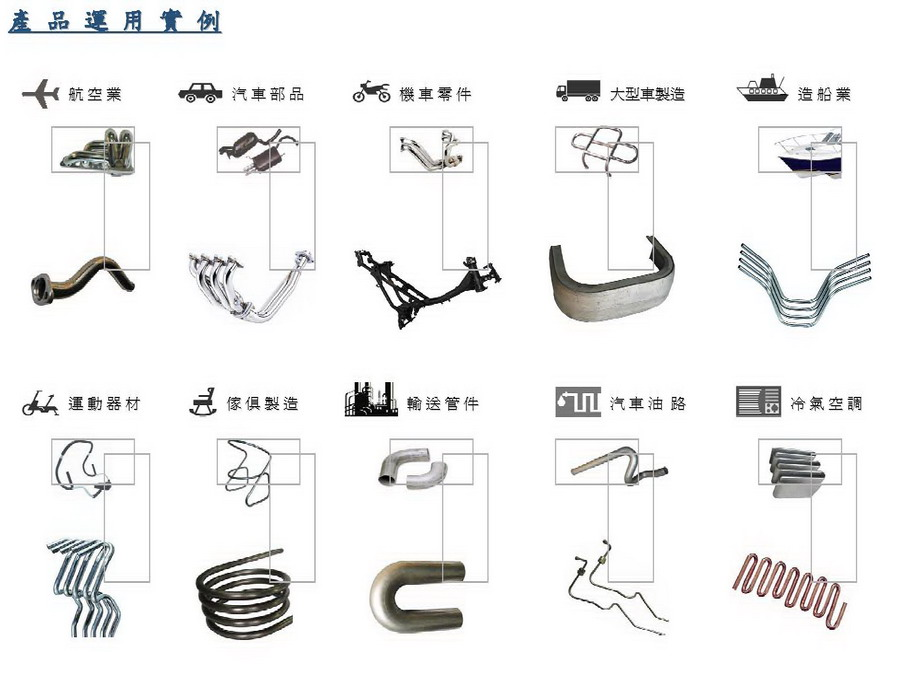

Transportation industry: motorcycles, bicycles, automobile exhaust pipes, brakes, fuel supply lines, steering gears, air conditioning lines, seats, balancers, bumpers, window frames, handlebars, frames, etc.

Furniture industry: indoor and outdoor tables and chairs, office desks and chairs, shelves, beds and other furniture.

Leisure industry: fitness equipment, baby carriages, strollers, amusement facilities.

Heating and cooling industry: water heaters, electric heaters, gas stoves, refrigerators, air conditioners, etc.

Heavy industry: boilers, power plants, chemical plants, diesel engines, shipbuilding and other piping.

Other industries: household goods, rehabilitation medical equipment, bathroom equipment, decoration industry, construction industry, agriculture, aviation industry.

相关产品

Precise control through 3-13 axis servo motors;

Can realize left and right bending functions of 1-4 layer molds;

Can realize large radius or spiral product bending, with push bending function;

Industrial computer system has 3D interference inspection function;

Can connect robots and 3D measuring instruments, etc.

Fully automatic CNC tube bending machine, tube bending and mold transfer servo control (hydraulic control is available), cornering and feeding are servo controlled, clamping and core pulling are hydraulically controlled. It can achieve large radius bending and has push bending function. The equipment uses a 10.0-inch touch screen, English or multiple language modes, PLC controller (optional Windows XP industrial system). Air cooling/water cooling/oil cooling are available. It has a partial automatic lubrication function. Electrical and hydraulic components are imported from Japan, France, Germany and other countries.

Precise control through 3-13 axis servo motors;

Can realize left and right bending functions of 1-4 layer molds;

Can realize large radius or spiral product bending, with push bending function;

Industrial computer system has 3D interference inspection function;

Can connect robots and 3D measuring instruments, etc.

DW38CNC-3A-2S fully automatic pipe bending machine is servo and hydraulic driven. The electrical appliances centrally control the bending angle, feeding accuracy, and pipe rotation accuracy. The bending head can change molds left and right. The hydraulic control clamping, guiding, head up and down mold changing, mandrel, mechanism, etc. have their own independent cylinders. When the bending arm bends the pipe, under the control of the hydraulic system, the clamping, guiding, mandrel, and bending parts coordinate with each other to complete high-quality bending. It is an economical and practical general equipment.

The 63CNC-4A-2S automatic pipe bending machine is a high-performance CNC pipe bending equipment featuring 4-axis linkage (4A) and dual servo drive (2S) technology, capable of processing carbon steel pipes with diameters up to 63mm and wall thickness ranges from 1.0-4.0mm. Equipped with a high-precision CNC control system, it achieves repeat positioning accuracy within ±0.1mm and features automatic rebound compensation for complex three-dimensional bends. The fully automated workflow includes automatic feeding, precise positioning, bending formation, and material removal, with optional modules for automatic loading and inspection. The touchscreen interface supports graphical programming and CAD file import, storing hundreds of machining programs. Ideal for precision pipe processing in automotive exhaust systems, furniture hardware, fitness equipment, and related industries, this machine improves efficiency by over 50% compared to traditional equipment while significantly reducing production costs.

The pipe bending machine is hydraulically driven, with high bending angle accuracy and compensation value.

The turning angle and feeding are driven by servo motors, with high efficiency, accurate turning angle and feeding.

It is especially suitable for pipe processing with many spatial angles and high precision requirements. Such as: the production of automobile oil pipes, air conditioning pipes, motorcycles, bicycles and other frames.

The fully automatic pipe bending machine can bend three-dimensional pipes.

Fully automatic CNC tube bending machine, tube bending and mold transfer servo control (hydraulic control is available), cornering and feeding are servo controlled, clamping and core pulling are hydraulically controlled. It can achieve large radius bending and has push bending function. The equipment uses a 10.0-inch touch screen, English or multiple language modes, PLC controller (optional Windows XP industrial system). Air cooling/water cooling/oil cooling are available. It has a partial automatic lubrication function. Electrical and hydraulic components are imported from Japan, France, Germany and other countries.

Precise control through 3-13 axis servo motors;

Can realize left and right bending functions of 1-4 layer molds;

Can realize large radius or spiral product bending, with push bending function;

Industrial computer system has 3D interference inspection function;

Can connect robots and 3D measuring instruments, etc.