The 38CNC-3A-1S fully automatic CNC pipe bender is a high-performance bending machine with key specifications: Maximum bending capacity for pipes (or materials with equivalent wall thickness) typically reaches 38mm diameter. Featuring a three-axis (X/Y/Z) CNC control system and a servo spindle for precise motion, it allows flexible angle adjustments from 0° to 190° with high repeatability accuracy. The standard hydraulic drive ensures stable operation and robust performance. Its memory storage function enables pre-programmed multiple processing sequences. This versatile equipment handles complex spatial bending operations for carbon steel, stainless steel, copper, aluminum, and other metals, finding widespread applications in automotive, HVAC, and furniture manufacturing. With advanced automation capabilities, it delivers exceptional production efficiency.

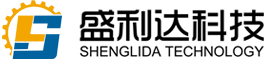

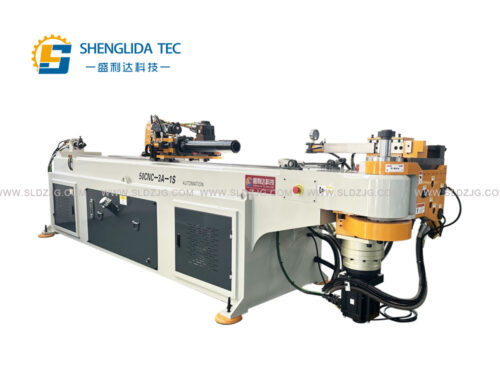

The 50CNC-3A-1S is a high-performance fully automatic CNC pipe bender. The name “50” indicates a maximum bending capacity of 50 mm pipe diameter, “CNC” stands for Computer Numerical Control, “3A” typically refers to three servo axes (feeding, bending, and lifting) working in coordination, and “1S” denotes a set of molds. This equipment integrates precision machinery, servo drives, and CNC systems to efficiently and accurately perform complex spatial bending operations. Operators only need to input programs, and the machine can automatically complete feeding, rotating, bending, and spatial cornering movements. With high repeatability positioning accuracy, it significantly enhances production efficiency and product consistency.

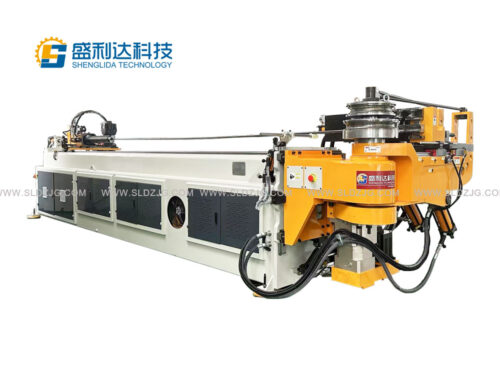

The 89CNC-6A-3S fully automatic pipe bender is a high-efficiency CNC bending machine specifically designed for metal pipe processing. Equipped with a CNC control system, it supports three-dimensional bending operations and features high precision with accurate repeat positioning. Suitable for processing pipes made of stainless steel, carbon steel, copper, aluminum, and other materials, this equipment integrates a 6-axis servo drive system, automated feeding mechanism, and 3D simulation capabilities. It allows multi-program storage and enables batch production of pipes with complex angles and curves. This bending machine has hydraulic clamping function and anti-wrinkle and anti-bending function, the maximum bending diameter can reach 89mm, wall thickness can reach 6mm, Widely used in automotive, furniture, aerospace, and related industries, it boosts processing efficiency by over 30%, serving as an intelligent solution for modern pipe component manufacturing.

Equipped with an industrial-grade computer control system and a touchscreen interface, this equipment supports bilingual operation (Chinese-English). Users can select manual, semi-automatic, or fully automatic modes as needed. Featuring real-time fault detection, it displays anomalies and provides troubleshooting suggestions. Designed for aerospace, automotive parts, HVAC refrigeration, and steel pipe furniture industries, the CNC pipe bender achieves high-precision bending through programming. It allows independent configuration of five operational sequences and ten speed ranges for individual pipes, significantly enhancing efficiency while reducing operational risks.

NC series pipe bender machine is equipped with CNC control unit, which has the advantages of convenient operation, high bending accuracy and high cost performance.

1.As a practical semi-automatic solution for small and medium-sized manufacturers, its rational design and minimalist style provide optimal spatial layout for pipe bending operations.

2.The CNC system with user-friendly interface enables flexible parameter settings.

3.Encoder ensures precise and stable bending angles.

4.Multiple processing modes stored for seamless program switching.

5.Automatic counting and power-off memory functions.

6.Hydraulic cooling system guarantees long-term stable operation in high-temperature environments.

7.Spindle undergoes special heat treatment process.

8.All components pass strict quality inspection meeting ISO 9001 standards.

9.Electromagnetic valves and integrated circuits independently control each bending action, effectively extending hydraulic component lifespan.

10.Suitable for processing various materials including steel, stainless steel, aluminum, and copper.

The 63CNC-4A-2S automatic pipe bending machine is a high-performance CNC pipe bending equipment featuring 4-axis linkage (4A) and dual servo drive (2S) technology, capable of processing carbon steel pipes with diameters up to 63mm and wall thickness ranges from 1.0-4.0mm. Equipped with a high-precision CNC control system, it achieves repeat positioning accuracy within ±0.1mm and features automatic rebound compensation for complex three-dimensional bends. The fully automated workflow includes automatic feeding, precise positioning, bending formation, and material removal, with optional modules for automatic loading and inspection. The touchscreen interface supports graphical programming and CAD file import, storing hundreds of machining programs. Ideal for precision pipe processing in automotive exhaust systems, furniture hardware, fitness equipment, and related industries, this machine improves efficiency by over 50% compared to traditional equipment while significantly reducing production costs.

■The machine can feed up to 1500mm at a time, servo feeding (feeding length can be customized according to customer requirements)

■The machine can cut multiple pipes, and can cut at least 4 Ф25mm pipes at a time.

■Feeding can be repeated multiple times.

■The machine can cut steel pipes of different diameters (Ф25-125mm) by changing the jaws.

This machine is used for three-dimensional cutting of square tubes, round tubes, oval tubes and other pipes. It has a stable structure, no deformation of the pipe mouth, and no burrs. The cutting range is wide, 10-80mm, and the cutting tail is within 50mm. One person can operate multiple devices, and the efficiency is 3-5 times that of ordinary pipe cutting machines.

The pipe bending machine is hydraulically driven, with high bending angle accuracy and compensation value.

The turning angle and feeding are driven by servo motors, with high efficiency, accurate turning angle and feeding.

It is especially suitable for pipe processing with many spatial angles and high precision requirements. Such as: the production of automobile oil pipes, air conditioning pipes, motorcycles, bicycles and other frames.

The fully automatic pipe bending machine can bend three-dimensional pipes.